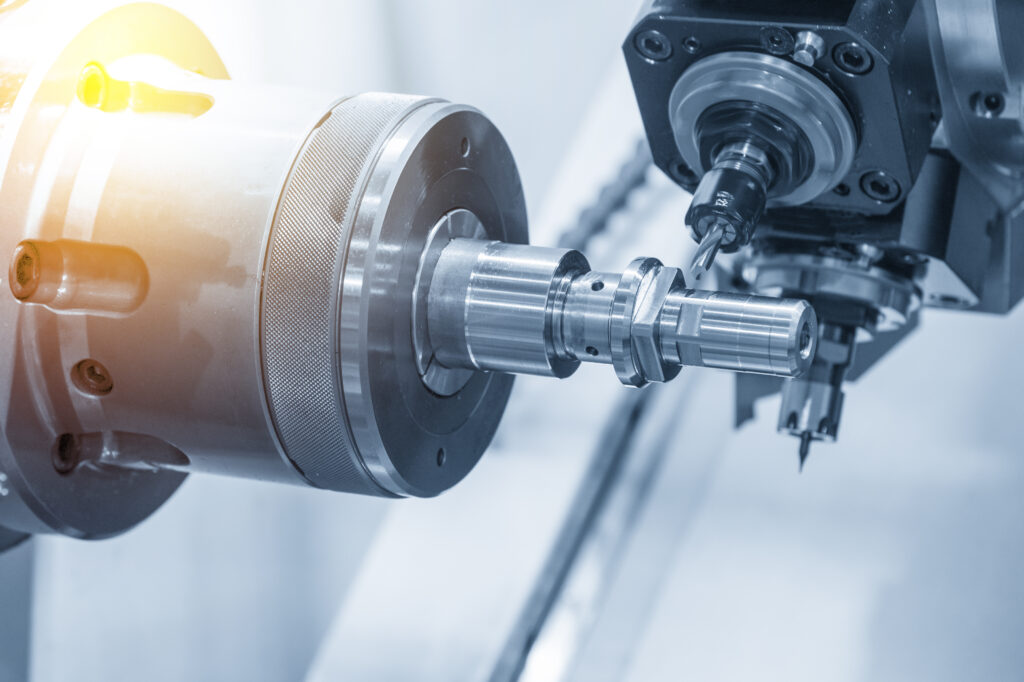

We have eight grinders capable of grinding ODs (outside diameters), two with the ability to grind ODs and IDs (internal diameters) concurrently. All machines have in-process gauging. This includes CNC-controlled Studer machines with the capability of grinding multiple diameters in one chucking, non-round and thread-grinding capabilities, as well as IDs. Capacities of 13.75-inch OD by 39.00 inches are possible, and all CNC machines have coolant temperature-controlled to 20.0°C ± 0.5°C.